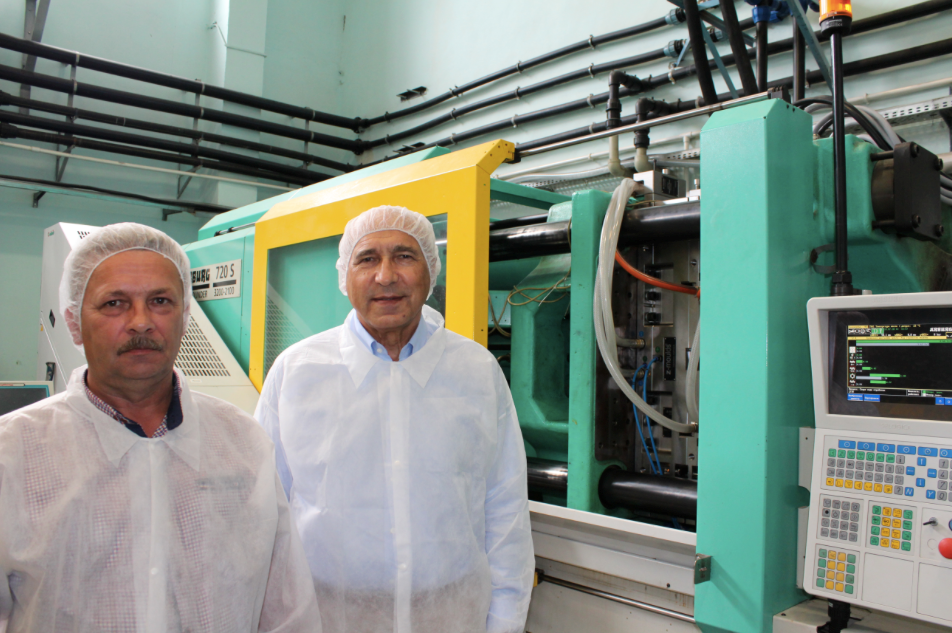

JSC “LACMA” is a plastic packing manufacturer, founded in 1992. The main products of the company are screw caps, spouts for doy packs and flip top caps. The company employs 91 people and its annual production volume constitutes 700 million caps. The company supplies more than 60 producers of beer, carbonated/noncarbonated mineral water and carbonated drinks.

LACMA purchased two 48-slot high-performance hot-channel injection moulds with temperature controllers for production of the screw caps for PET bottles. Just over 71% of the €1.06 million investment was financed with a EU4Business-EBRD Credit Line Loan.

The purpose of the investment was to reduce the consumption of materials and waste per unit of output in the production of plastic caps for plastic bottles with a threaded neck. Furthermore, new equipment is more energy efficient than the existing equipment. It will also increase the production capacity for bottle caps by 22%, and it reduces the consumption of polyethylene used in the manufacturing process by around 32-34%.

After the successful project verification, the company receives 15% of the loan value as a grant incentive, funded under the EU4Business initiative of the European Union. The project verification was carried out under the special COVID-19 rules set by the EU, which ensure that investment projects can be verified despite COVID restrictions and that investors can receive their grant. The timely verification and grant payment is important to all companies, but even more so to companies that contribute to safeguarding that local production can supply other processing industries and that contribute to employment in the country.

With the investment, the company now meets a wide variety of European standards, including:

| Loan Amount | € 757,244 |

| Grant amount | € 113,586 |

| EU Directives met | Regulations on machinery, on waste, on health and safety of workers |

| Invested in | Two high performance hotrunner 48-cavity injection mould, with temperature controller for the production of screw caps |