Improving animal welfare in pig farming

Zootechnologia LLC, a Ukrainian enterprise without foreign investments, is situated in the Kherson region.

Improving worker motivation and process efficiency in agriculture

‘Zlatopil’ is an agricultural company that has been operating since 1996.

Contributing to secure food supply

The company Vladana is an important agrarian enterprise located in the Suma region in North-Eastern Ukraine.

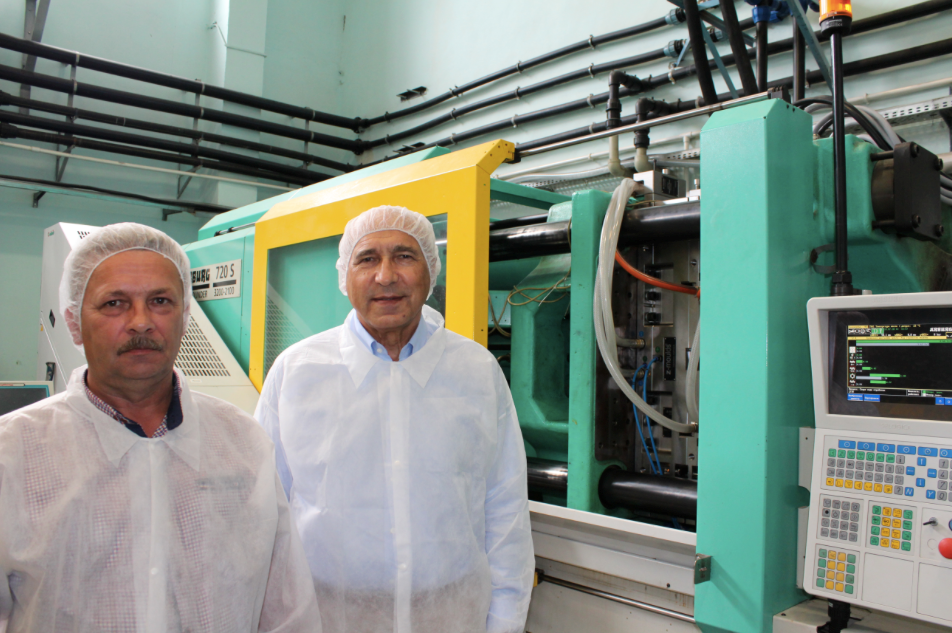

Reducing raw material input in bottle cap production

JSC “LACMA” is a plastic packing manufacturer, founded in 1992. The main products of the company are screw caps,